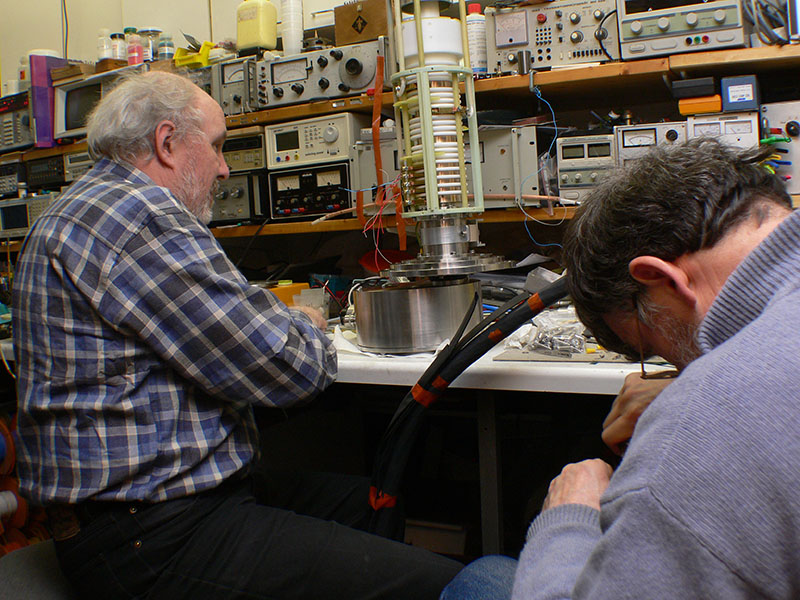

Precautions for slip ring maintenance

As part of industrial equipment, conductive slip rings are widely used in many electromechanical equipment. As a kind of movable and wearable parts, the slip ring has a limited lifespan, so how to extend the life of the slip ring has become a critical issue.

2025-01-08 09:38 by admin

As part of industrial equipment, conductive slip rings are widely used in many electromechanical equipment. As a kind of moving and easy-to-wear part, the slip ring has a limited service life, so how to extend the life of the slip ring has become a crucial issue.

As a leading domestic slip ring manufacturer, JINPAT Electronics has very rich experience in designing high life conductive slip rings. In addition to adopting excellent design and better materials, the maintenance of conductive slip rings during use is also a very important way to improve the service life. Next, I will give you a brief summary of some small knowledge about the use and maintenance of conductive slip rings.

First of all, when ordering the conductive slip ring, the environmental adaptation parameters of the conductive slip ring should be determined according to the use environment of the conductive slip ring and the assembled peripheral equipment, and then the accurate data of the conductive slip ring should be given to the manufacturer to ensure that the customized conductive slip ring has the ability to work Stably for a long time in the environment of anti-vibration, anti-salt spray, high and low temperature, high dust and high humidity.

Whether the installation is correct or not is also a factor affecting the life of the connector slip ring, so it must be installed correctly according to the installation instructions. Among them, it should be noted that a reasonable radial clearance is ensured during the installation process. If the radial clearance of the conductive slip ring increases, the load area of the conductive slip ring will decrease, and the maximum rolling body load will increase, reducing the life of the conductive slip ring.

During storage and use, the maximum voltage and current that the conductive slip ring can withstand should be avoided, and it should be stored with the terminal application equipment in a cool, dry, non-corrosive place, strong acid and strong alkali corrosion in order to avoid bearings, etc. The life of the conductive slip ring is reduced due to corrosion of the metal parts and internal electrical components.

Conductive slip rings operating in special environments must be customized. For example, the high and low temperature impact resistance of conductive slip rings, but if the order exceeds the default value of standard products or ordinary products, it must be customized. The normal operating temperature range of JINPAT ordinary conductive slip rings is -20°C ~ +60°C. If the conductive slip ring continues to operate in an environment exceeding this value, the life of the conductive slip ring will also be affected. In addition to high and low temperature shock, physical shock will also reduce the life of the conductive slip ring, so the conductive slip ring should also be avoided from violent external shock during use.