How do JINPAT slip rings help semiconductor equipment overcome the challenges of dirt and heat?

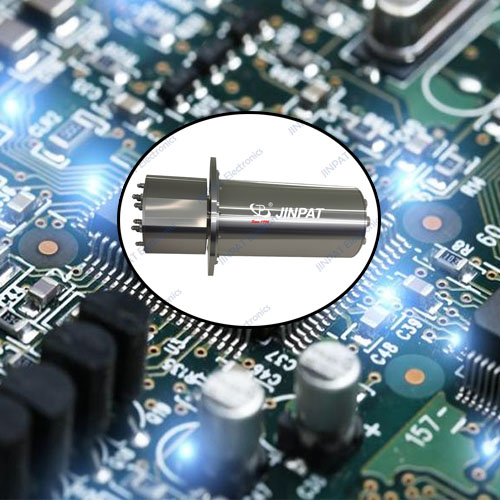

JINPAT LPT hollow shaft slip rings are designed for high-temperature (>200℃) and vacuum environments in semiconductor equipment. With special materials and sealing technology, they eliminate contamination and leakage, ensuring the purity and stability of core processes.

2025-11-12 14:49 by

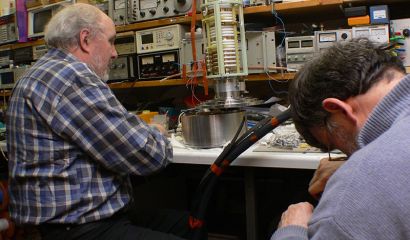

In the field of semiconductor precision manufacturing, equipment stability and environmental cleanliness affect chip performance and yield. In critical processes such as chemical vapor deposition and physical vapor deposition, equipment needs to operate under continuous high temperatures and ultra-high vacuum environments. JINPAT LPT hollow shaft slip rings are specifically designed for such demanding conditions, with their core advantages manifested in two main aspects:

1. High-Temperature Resistant Design: Ensuring Stable Thermal Transmission

The JINPAT LPT slip ring has undergone specialized optimization in both materials and structure for the high-temperature operating conditions of semiconductor equipment. Its internal components utilize special high-temperature engineering plastics and ceramic insulation materials to ensure stable electrical performance and undiminished mechanical strength in environments exceeding 200°C. The SUS304 stainless steel shell provides excellent high-temperature strength and corrosion resistance, ensuring the overall structural integrity and long lifespan of the slip ring under thermal stress.

2. Vacuum-Protecting Design: Safeguarding the Purity of Process Chambers

To meet the stringent requirements of vacuum processes, this slip ring implements a systematic anti-contamination and sealing solution. The rotor end strictly adheres to an oil-free design and uses special alloy terminals such as stainless steel, eliminating the risk of volatile contaminants and copper ion precipitation at the source. Simultaneously, precise dynamic sealing technology effectively isolates the stator and rotor ends, ensuring the airtightness of the vacuum environment, preventing leakage, and safeguarding the core cleanliness of chip manufacturing.

In summary, the JINPAT LPT hollow shaft slip ring, with its two core capabilities of high temperature resistance and vacuum retention, provides a solid guarantee for the reliable operation of semiconductor equipment under extreme conditions, and is an ideal bridge connecting rotating platforms and fixed structures, transmitting energy and signals.