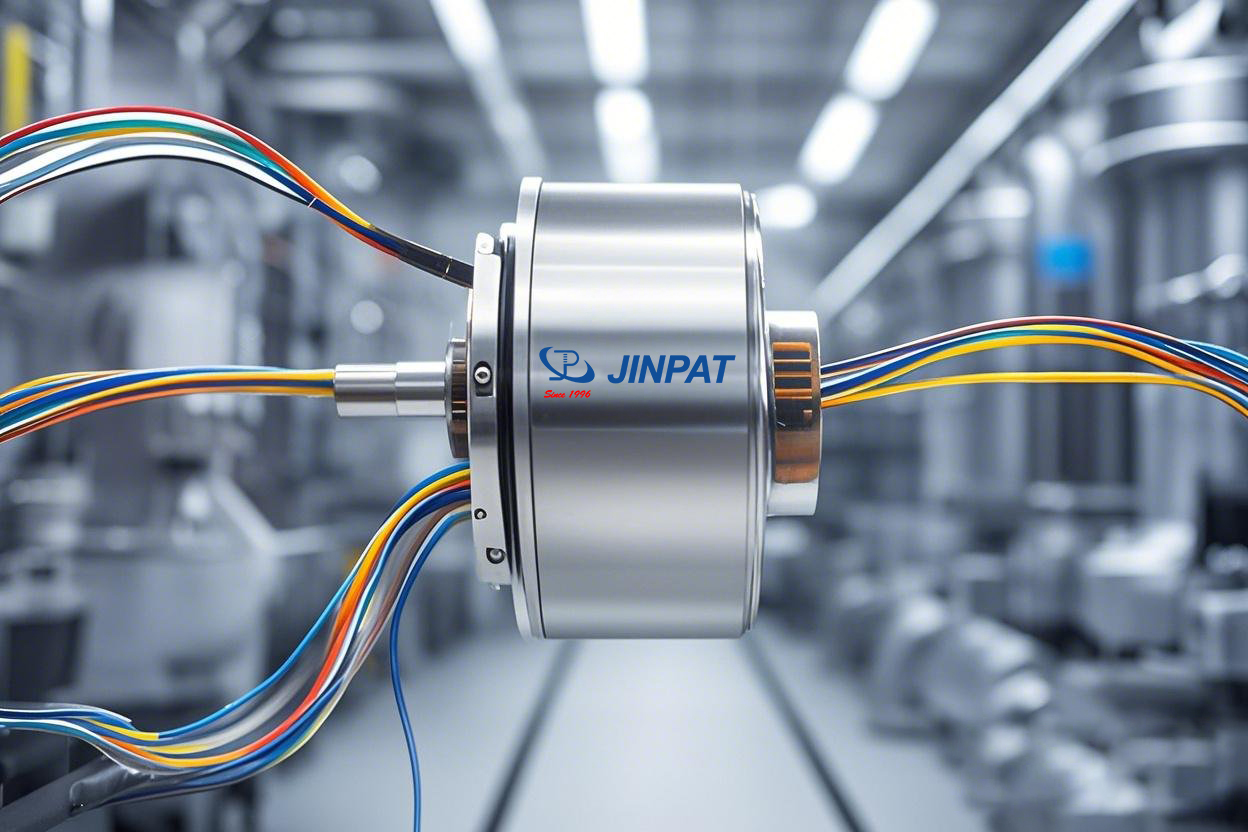

In the slip ring industry, customization is essential, just as in other industrial sectors. As a globally renowned manufacturer, JINPAT has achieved an impressive 95% customization rate for its products. Among these, hollow shaft slip rings stand out as a key product line, offering diverse design variations that integrate telecommunication signals, gas-liquid modules, multiple signal channels, power modules, and even optoelectronic and high-frequency components.

JINPAT’s hollow shaft slip rings are categorized into standard and custom models. The standard versions primarily transmit electrical current and come in specifications of 2A, 5A, 10A, and 15A. Notably, the 12.7mm aperture model is unique, only available in a 2A version without a 15A counterpart. Other standard aperture sizes support 5A, 10A, and 15A, designed to align with industry-standard electrical requirements, ensuring broad compatibility. However, when specialized applications demand unique configurations, customization becomes essential.

JINPAT’s hollow shaft slip rings offer extensive customization options, including different shell materials, shaft compositions, and structural designs. A recent example is the LPT050-0601 model—a compact design featuring six 1A current paths. While its parameters seem simple, its structure is highly sophisticated. Constructed from SUS304 stainless steel, it significantly differs from other hollow shaft slip rings in JINPAT’s lineup. The stainless steel housing and shaft, combined with an advanced anti-vibration structure, provide superior impact resistance. With an IP64 protection rating, this model guarantees stable operation in harsh environments.

Beyond custom slip rings, JINPAT is actively exploring modular integration. By utilizing the hollow shaft’s central through-hole, additional components such as fiber optic slip rings, high-frequency slip rings with flanges, and capsule slip rings can be seamlessly incorporated. This modular approach enhances flexibility and reduces development time, enabling faster adaptation to new industrial demands. With extensive experience and strong technical expertise, JINPAT continues to develop specialized slip rings for engineering machinery, special vehicles, and other applications requiring complex signal and power integration.