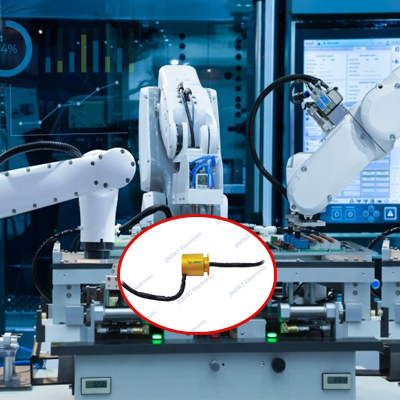

JINPAT LPT integrated slip ring, combining two slip rings into one, empowers robotic arms.

The JINPAT LPT hollow shaft slip ring adopts a unique double-layer structure integrating a large slip ring and a small slip ring. Its compact design solves the problems of space constraints and multi-signal transmission in robotic arms, and its lifespan exceeds 10 million revolutions, ensuring long-term reliable operation.

2025-12-10 15:51 by

In the pursuit of industrial automation, every joint of a robotic arm requires reliable and durable "nerves and blood vessels" to transmit power and signals. JINPAT LPT series hollow shaft slip rings are a core component designed precisely for this purpose.

Robotic arm design often faces two major challenges: extreme

ly limited internal installation space and the need to simultaneously transmit multiple signals, including power, control signals, data, and even video. Traditional single slip rings often cannot handle all of these requirements. The JINPAT LPT slip ring innovatively employs a two-layer structure with a large slip ring nested within a smaller one, compactly integrating power transmission and precision signal transmission modules. This design directly solves the engineering challenges arising from insufficient length or the need for independent processing of special signals, simplifying the overall structure and improving system reliability.

The product's core advantages lie in two aspects: First, its highly integrated compactness, which maximizes the use of the robotic arm's axial space, avoiding the complexity and instability of connecting multiple external components;And second, its exceptional durability, with a standard service life exceeding 10 million revolutions. For manufacturing industries seeking to increase production capacity and reduce downtime, this means the robotic arm can withstand long-term, high-intensity continuous operation, significantly reducing maintenance costs and frequency, and ensuring production continuity.

In conclusion, the JINPAT LPT hollow shaft slip ring, with its ingenious spatial integration and durable quality, addresses the core needs of modern robotic arm design. It is not only a technical component enabling 360-degree infinite rotational transmission, but also a key to ensuring the continuous and efficient operation of the production line. Choosing JINPAT means choosing reliable and durable core components, a solid step towards a smarter and more efficient industrial future.